This video covers creating a detailed professional surface cast mold for creating mechanical parts. Ideal for working on medium-sized projects, this process of pouring a high quality material around a lower quality core creates a highly accurate, yet economical part. This process can be used in automotive, mechanical, fine art and film special effects uses.

This video teaches you a couple of tricks on installing crown molding, base boards, and casing. The tutorial advises the use of a negative rake blade to ensure a smooth cut. As always, you'll want to measure twice and cut once, but as far as your limbs go, don't cut those at all.

Master potter Simon Leach is so good at what he does because he follows his own advice: practice, practice, practice! In this tutorial by Simon Leach, you'll watch Leach as he throws and sculpts a very pretty textured tea bowl. Using his fingers to help mold the tall form, Leach skillfully applies a lower rim and then adds a criss cross pattern by slapping a textured mold onto the pot's side.

Check out this video for creating a one piece mold using a repro laminating system. This is a professional video not for beginners. The repro laminating system is ideal for working on medium-sized projects, this process is easier, faster, and more economical than the epoxy laminating system. This process can be used in automotive, mechanical, fine art and film special effects uses.

Check out this video to learn how to make a professional epoxy fiberglass layup and epoxy laminating systems. This process is ideal for working on larger projects, a typical 'fiberglass layup' is a popular process for those who need a large, strong, and lightweight tool.This process can be used in automotive, mechanical, fine art and film special effects uses.

Watch this video to learn how to use Rebound 25 brush-on silicone rubber to make a mold. This two part video series is very detailed and helpful! You could make a mold of anything you choose!

It is important that your mortar is not cracked so that animals and insects cannot get in. Also, it can prevent water damage and mold. Greg Lim, a professional handyman and residential property manager, shows you a do-it-yourself method for fixing your brick wall by applying mortar.

In this two part video you'll learn the complete process for casting duplicates of a miniature figure. How to make the rubber mold in two parts and how to cast the miniature duplicate. A two part mold is the kind of rubber mold you make for complex minis like figures, warriors, wizards, dwarves etc. You'll learn everything you need, and exactly what to do to duplicate your own miniature fantasy characters.

Check out this video for how to create simple one piece silicone rubber molds. This technique is ideal for smaller projects (less than 12" x 12"), this is the easiest process for creating parts, patterns, tools, & molds. We demonstrate creating a silicone rubber mold and then the casting of parts with Repro, epoxy casting resins and polyurethane elastomers. This process can be used in automotive, mechanical, fine art and film special effects uses.

Chef Dominic Palazzolo teaches you how to make the always useful sugar bottle mold. This is particularly helpful for cake decorators, theater, and propmakers. You can use a regular bottle to make this mold.

Belly casts are the new keepsake for pregnant women that last and display well; learn how to cast a pregnant belly in this free video series on body molding tips.

Terri Sproul shows you how to Work with Paperclay and Molds. Make a ball of paperclay and push it firmly into the center of the home-made or ready-made Mold. Make the surface of the Paperclay level with the surface of the Mold, adding more Paperclay if necessary, and removing any excess with your fingers. The molding putty that the Mold is made from is flexible, so hold the edges of the mold with your fingers and gently push the center of the Mold with your thumbs, this will push the molded P...

This how-to video series is a step-by-step guide to molding fiberglass. These videos give a simple introduction to fiberglass mold construction, explained using a model aircraft cowling but the same technique applies to any fiberglass sculpture. The entire process is detailed from plug, to mold, to finished fiberglass part. Follow along with the eight steps: develop the plug, construct the parting board, lay up the mold, release the mold from the plug, prepare the mold for fabrication, lay up...

Tired of boring old soap that you get from the store? Learn how to melt and mold soap from our soap expert in this free video clip series.

This video is an introduction to rawhide art and the process of its creation and appreciation. Candace Copeland uses many media in her passion of creating art. One of her specialties is rawhide art.

This video shows the viewer how to repair a section of damaged molding surrounding a door or window. The method shown uses WD40 and polyester resin. Firstly an undamaged section of the molding is sprayed with WD40 and then covered in resin. Once the resin has hardened the WD40 allows it to be removed and used as a mould. The mould is then sprayed with more WD40 and is filled with new resin. This is allowed to harden and then removed. The resin replica of the molding is then sanded and cut to ...

Chef Dominic Palazzolo teaches you how to make a complex lace mold for confections. He gives a great breakdown of the mold process and how best to implement the mold to your ingredients.

This video tutorial shows how to use Smooth-On's ReoFlex urethane mold rubber to cast a simple 1-piece block mold. Learn how to mix, pour, form, and create a one piece mold to create duplicates of an original object.

Cake pops are generally made in a circular shape from vanilla or chocolate cake, then dipped into chocolate or candy melts and sprinkled with adornments, but that doesn't mean you can't have some fun tweaking the shape a bit.

This excellent detailed video demonstrates how to create rigid molds with a fast cast urethane. Ideal for smaller models/molds with a flat side, fast-cast urethanes are widely used for their ease of use, low cost, and quick de-mold times. However, their use requires careful application of release agents. This process can be used in automotive, mechanical, fine art and film special effects uses.

This video illustrates in great detail how to create a perfect urethane rubber mold. Urethane Rubber molds are widely used when a flexible mold material is required and a more expensive or less abrasion-resistant silicone rubber is not desired. However, their use requires careful application of release agents. This process can be used in automotive, mechanical, fine art and film special effects uses.

This is an excellent video that covers creating a clear silicone rubber mold to deal with a complex parting line or irregular shape. When a project requires a complex parting line, it is often easier to pour the entire mold in one process with clear rubber, then cut your parting line. This process also saves at least a day in creating the mold. This process can be used in automotive, mechanical, fine art and film special effects uses.

This video segment will show you how to make a simple two-part mold using Urethane RTV molding rubber. The same process can be used for silicone molds.

This three part instructional sculpture video demonstrates how to make a two part plaster mold. Make a plaster mold to make stop-motion animation puppets from clay models. A plaster mold can make casts out of almost any material. This model will be cast out of foam rubber with a movable metal skeleton.

This video shows you how to make a flexible mold using Amazing Molding Putty. You can make molds of just about anything that has the desired shape and texture you want.

This how-to video tutorial gives instruction as how to build a mold and the steps of how to make the mold out of RTC plastic, from application of the plastic mix to degassing.

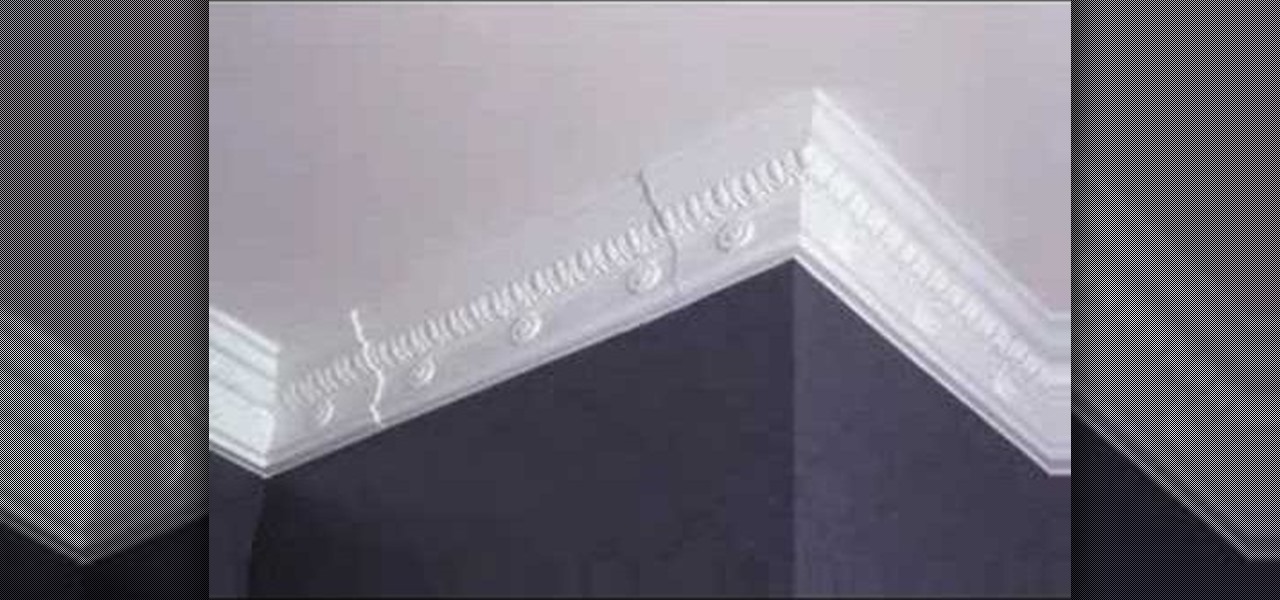

Cutting crown molding is simple with these tips from Tim Carter. Your crown molding will easily fit any inside or outside corner if you follow Tim's tips. Simple crown molding will be even easier and complex crown molding will be doable.

A look at understanding crown moulding. Check out this Woodworking Underground four-part video tutorial to learn about making or installing crown moulding for your home. This how-to video is a must-watch for all furniture and woodwork enthusiasts.

Check out this video tutorial on how to make a fiberglass mold layup for car speakers. For fresh molds you must put several layers of wax on and I would consider PVA as well if the mold is less then a week old. Always use PVA (or equivalent) on your plug surface before molding.

In order to make a Silicone Ring Mold you should first get a small plastic container. This will be your mold box. First, you should cut the bottom out of the container. Next, use double sided tape to stick the ring down to the base of this. Next, secure the mold walls to the base. Now, mix the silicone mix in a separate mixing cup. Make sure you mix this thoroughly until the color is uniform. Now pour the silicone into the mold in a fine stream on the side of the ring, this will help prevent ...

snow mold occurs in round patches of grass in the lawn. The patches contain a fussy substance (the mold), that appears in grey or pink; the most dangerous of the two. Mold is formed whenever a lot of snow is left on the lawn for a long period of time, this causes the mold to grow underneath. Late fertilization with a lot of nitrogen promotes mold. Dead grass or thatch can cause mold to develop. Gently raking allows airflow into the grass and promotes new grass growth. The putting down of gras...

She begins by taking something she has molded with Amazing Mold Putty. She uses Magic Gloss resin which cures with UV light to fill the silicon mold and sprinkles some glitter onto the resin. She emphasizes that she's doing this indoors, because the resin will harden when exposed to light. She takes it outside to cure in the sunshine and says it will take about 15 minutes to cure. When it's done, she rolls a ball of Pardo clay. She pops the molded piece out. She presses the molded resin piece...

In this how-to video series, learn the three M's of crown moulding installation projects - choosing the right materials, accurately measuring your moulding, and using your mitre saw to cut for an exact fit. Crown moulding can add a beautiful touch into your home. Watch this video home improvement tutorial series and learn how to install crown moulding.

If you're looking to dress up an ordinary room, think about installing crown molding (also spelled moulding). Very few additions make a visual impact like crown molding, which gives a subtle yet elegant design element to any space. And with the proper tools and set up, installation can be easy. While wood is a common choice for crown molding, urethane is also a popular material. For a recent project we installed Fypon urethane crown molding, which is lightweight, flexible and looks like solid...

This animation shows the various steps taken when creating an RTV mold. First, risers are put on the part to allow air to escape from the final mold. A thin film is attached to the part, which will act as a seam for the final mold. A box is built around the entire structure, and it is filled with silicone rubber. Once the rubber has cured, the box and risers are removed, the mold is opened at its seam, and the original part is removed. Any type of urethane can now be injected in the mold to c...

Making Jello cakes or desserts is really fun, but removing them from the cake mold is really not. Jello has a reputation for being slippery, but it also gets easily sticky and difficult to work with without total ruin.

Mold is not good for your home or your health. It creeps across damp ceilings and shower curtains, leaving a musty smell behind. In this tutorial, handyman Jay Baker shows you how to rid your home of mold before it gets a chance to make you sick.

Check out this video tutorial on how to fiberglass a mold layup for car subwoofer speakers. If you want the best fiberglass subwoofer box, this mold layup will get you there. Just follow these car audio instructions to get a booming audio system in you vehicle. If you ever wanted to make your own speaker boxes, this is the way to go.

Watch this instructional video to make cheap molds for casting miniatures. You can then duplicate pieces for building your diorama or game terrain. Sculpt original forms using polymer clay, and layer on latex to make a cheap rubber mold. Or, you can use pre-made forms to press shapes into a soft mold. This video provides several modes of creating plaster forms and duplicates for miniature sculptures.

This sculpture and candy making video will show you how to make your own sculpted silicone candy mold. This process uses Sculpy/Fimo, Amazing Mold Putty, and white chocolate for casting custom candies! This video is really good for ice cubes and jell-o too!